- Enhet

- Antal

-

- Radmärke

Vill du bli kund?

Ansök om kundkontoProduktinformation

Det austenitiska stålet med beteckning 1.4435 (SS 2353) är ett s k syrafast stål innehållande krom, nickel och molybden. Stålet liknar 1.4432 men med skillnaden att i 1.4435 är halterna krom och nickel något högre. Hållfasthetsmässigt ligger 1.4435 marginellt högre än 1.4432.

Sömlösa rör som ledningsrör i hydrauliska system måste kunna formas och böjas utan att brista samtidigt som de ska under drift stå emot ett inre tryck som stundtals kan vara mycket högt. Sådana sömlösa rör i rostfritt stål är standardiserade i SS-EN 10216-5. Linköpings ståls erbjudande omfattar rör i stålsort 1.4435 med yttre diameter i intervallet 6-30 mm och väggtjocklekar mellan 1,0 och 4,0 mm. Sömlösa hydraulikrör tillverkas genom extrudering (strängpressning) med efterföljande kalldragning och glödgning i skyddsgas. Efter tillverkning kontrolleras rören till 100% avseende trycktäthet.

Tack vare högre halt molybden karaktäriseras 1.4435 av något bättre korrosionsmotstånd än 1.4404 i svaga syror samt vatten som innehåller klorider om nu inte kloridhalten är för hög. Sömlösa hydraulikrör i stålsort 1.4435 lämpar sig för ledningar i hydrauliska system som utsätts för aggressiva miljöer såsom exempelvis påträffas inom marin och offshore segmenten.

1.4435 uppvisar såväl mycket bra formbarhet och svetsbarhet så att vid behov utgör böjning, kallformning och svetsning av sömlösa rör sällan något problem. Rören underkastas omfattande provning för att försäkra att ingen risk för sprickbildning föreligger om rören ska böjas eller kallformas.

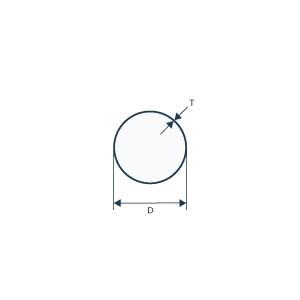

Sömlösa hydraulikrör i stålsort 1.4435 har blankglödgats i skyddsgas och ytorna är metallisk rena. Toleranserna på yttre diameter (D) och väggtjocklek (T), som stipuleras i detalj i EN 10305-1 och EN-ISO 1127, är ±0,08 mm för D och ±10% för T. Rakhet är god med högst pilhöjd normalt 0,002 gånger längden eller mindre. Det högsta hydrauliska trycket, som rören kan utsättas för är beroende av temperatur och självklart även av rörens diameter och väggtjocklek, och beräknas enligt ett förfarande som specificeras i EN 13480-3.